When I write, I disturb. When I show a film, I disturb. When I exhibit my painting, I disturb, and I disturb if I don't. I have a knack for disturbing.

—Jean Cocteau

It is a wonderful time for makers, we have terrific resources for getting things built now, with new resources appearing every day. Today we're going to talk about a few of the resources available to you, no matter where you live (almost).

We continue to be amazed at the creativity of the maker space, and the myriad of new designs and widgets available.

Creative designers like Dangerous Prototypes,

and Evil Mad Scientist, to name just a few,

are releasing dozens of new open sourced hardware designs every year.

As we travel and meet other people in the maker community,

we often get asked the same question :

"So how do get your stuff made, where can we get our things built?"

And usually what they are asking about are small quantities of things,

often the first prototypes of a new widget or design.

There are many companies (often refered to as CM's or Contract Manufacturers) that are happy to build thousands (or more) of a product for you, but if you ask them to build five (5) or ten (10) of them just to start, you will likely either get ignored, or be quoted a very high price. Fortunately for the maker community, there are some creative individuals who saw the need to provide these kinds of services. We've been working closely with several of these new service providers, and we'll be talking about a few of them today.

Fabricating your Printed Circuit Boards (PCBs)

Because Printed Circuit Boards are usually fabricated on a large panel, it can get expensive if you just need a handful of boards to prototype and test your design. Here in Portland, the Dorkbot PDX club had this problem, and one of their members, Laen, starting pooling together all of the projects for the club onto one large panel (it's called panelizing), so that everyone could share the expense of producing their PCB's. Soon they started offering that service to other clubs and to the public, and OSHPark was born. Once OSHPark was up and running successfully, then the folks at SparkFun decided to transfer their BatchPCB service to OSHPark, who has a much better web interface for submitting PCB designs.

OSHPark

Now that OSHPark has the increased volume of their original customers combined with the SparkFun BatchPCB customers, the turn-around-time to get your very own PCB's from OSHPark has decreased quite a bit. I routinely get very high quality, two layer, Gold (ENIDE process) PCB's from OSHPark in under two weeks from the time that I submit my Gerber files. Much of what I do would simply not be possible if it weren't for this wonderful service.

Fabricating your PCB Stencils (Stencils)

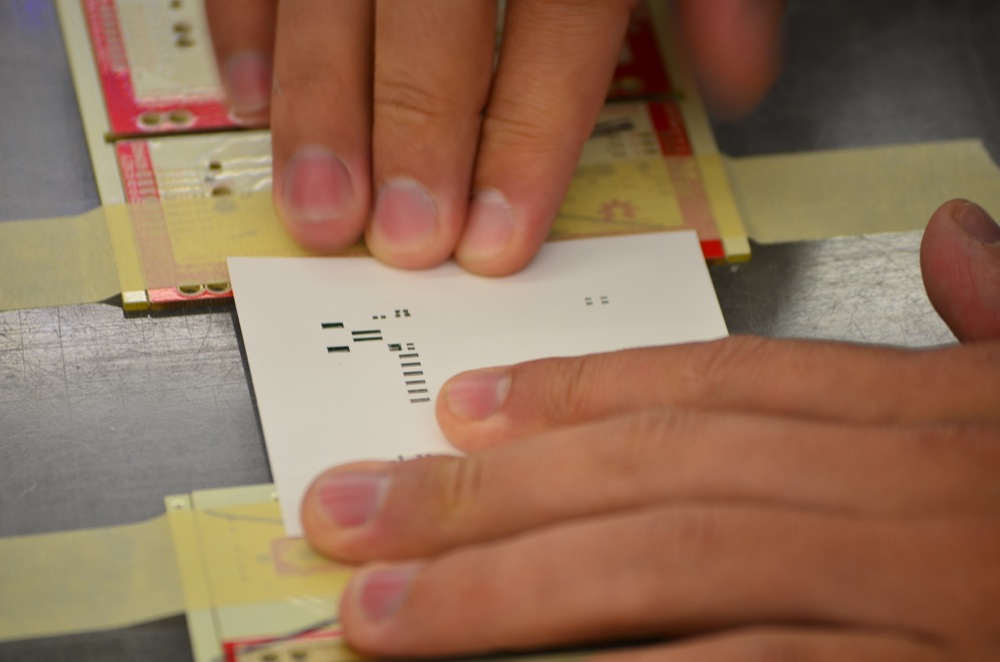

Most electronic components today are of the surface mount type,

where the componet is placed directly onto the srface of a printed circuit board using solder paste.

In order to apply the solder paste to the surface of the printed circuit board only where it is needed

(i.e. the leads of the components), a PCB Stencil is used.

PCB Stencils can be made out of a number of different materials, including Paper, Mylar, Aluminum and Steel. If you have access to a small laser cutting machine, you can fabricate your own using Reynolds Parchment Paper, which works very well for a small number of boards (2-5 typically), before it wears out. If you want to make more, you will need a good metal stencil.

OSH Stencils

OSH Stencils is a service that provides cost effective Polyimide (Kapton) stencils for short-run manufacturing. And they tell us that they will be offering metal stencils in the future.They recommend the range of 75-100 uses (i.e. boards) per Polyimide (Kapton) stencil, but if you are gentle with the stencils, you can often get more than that.

Assembling your Printed Circuit Boards (PCBs)

Okay, so you have your circuits boards and stencils, and box of fine pitch components that you can barely see - so how do you get them placed and soldered onto your circuit boards? Well, if you have good eyes (or a microscope) and a soldering iron, a hot-air soldering tool, and steady hands - you might be able to build them yourself. Which is often okay for the first one or two boards, but how about if you need five (5)? or a dozen?

Small Batch Assembly

Our friend, Bob at Small Batch Assembly saw the need to provide an affordable, low volume, electronics assembly service, and has created this new service for makers. He has developed a simple and easy web interface to submit your assembly job, including your parts list and assembly instructions. He'll put your parts on your board and then reflow solder your boards, shipping you back a completed assembly. Try it out, you'll love it.

Managing your Bill-of-Materials, Parts Lists, and Parts Ordering

As soon as you start having a few projects to manage, you'll quickly realize that spreadsheets don't quite cut it anymore. You will soon discover that you need a way to manage you parts orders from several vendors, and allocating those parts across several different projects, kitting up the parts for your board builds, etc.

Aligni

Our friend Jake created Aligni, a cloud-based software solution for product lifecycle and manufacturing management. Aligni can help you manage your parts inventory, your purchasing quotes, your builds and project lifecycles.

What is your favorite service or tool for building things?

Today we focused primarily on getting your printed cicuit boards fabricated and built, and in some upcoming articles we will be covering other topics like 3-D printing, packaging, and other services you'll need to get your next personal, school, or crowdfunded project built.

If you know of a new service or product for helping to get things built, we'd love to hear about it. Please use the comments section below, or tweet to us, we'd love to hear from you.

Happy Building!